Printing likewise holds huge importance in packaging as the first impression is the last impression and in packing labeling and silkscreen printing are used a lot. These aspects are not solely to give the product a more beautiful look but function and branding signs that may affect the performance of a product within the market. Realizing the relevance of these parts could assist the brands in making rational decisions about their packaging and therefore their brands. To understand more about the labelling and silkscreen, visit the website.

Labeling in the Context of Packaging

Labeling is not simply an efficient way of putting details that would be important to convey, it is a major tool in reaching out to a brand. We can achieve this by using labels as they are the interface through which the consumer gets to interact with the product in question. They contain important information concerning the product as well as instructions on how to use it and any precautions that should be taken while using it, hence helping in creating awareness of the product among the consumers.

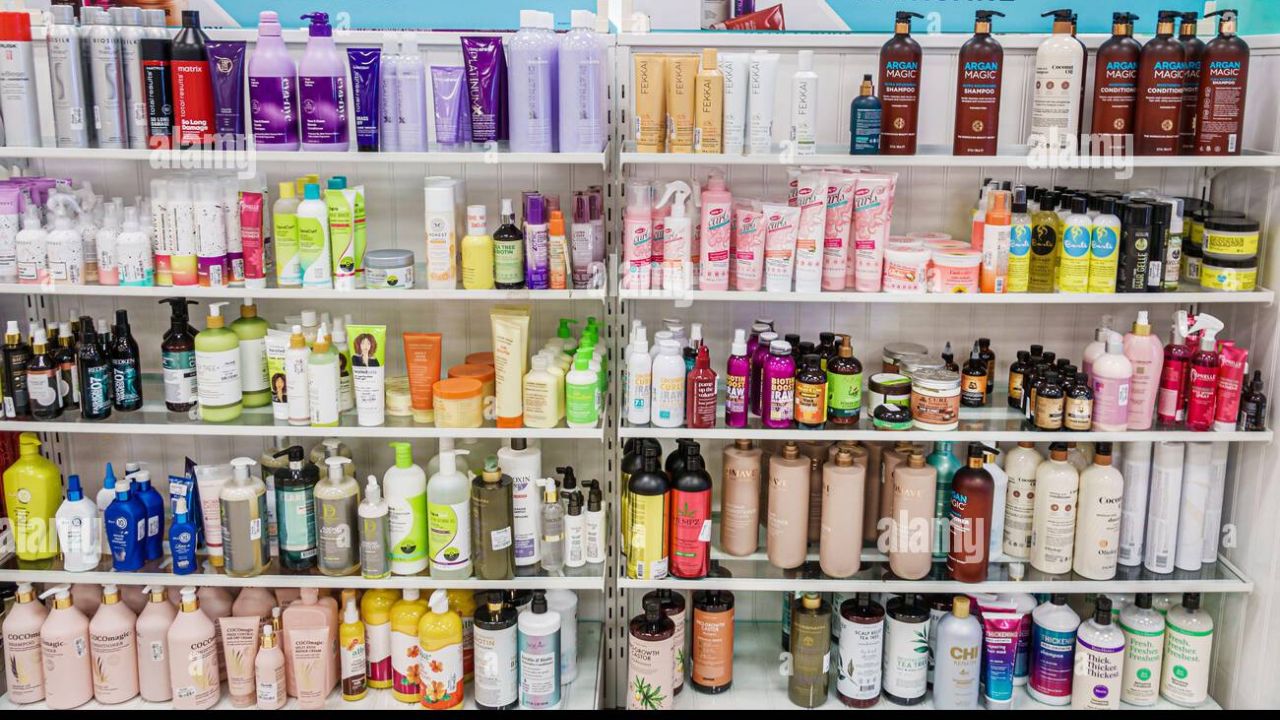

Also, it is important to note that labels are an organization’s representation of its brand. The layout and the color choice of a label, as well as the font used on a logo, can immediately convey a company’s ethos, the customers being targeted, and its competitive standing. For example, a skincare product manufactured under a high-end line may feature simple and classy packaging with low-intensity colors and a quality material finish. A label for an organic food product might use earthy colors and material containing organic concepts such as sustainability.

Labeling: Consequences and Functional Importance

Apart from the aesthetic function that can be attributed to labeling, there is a very significant practical need that cannot be overemphasized in packaging. Information operational for regulatory purposes includes data that may be legal to display, for instance, nutritional values of a food item or a warning that is on a chemical product. Failure to adhere to the labeling rules attracts legal consequences therefore posing a significant threat to the image of a brand.

It also helps in the process of tallying up and sorting labels about inventory. These include barcodes, QRCODE, and all other scannable areas in labels to enable tracking of stocks, managing the supply chain, and increasing the efficiency of their logistics. In the retail industry, these codes are useful to enhance the efficiency and speed of the transactions between the customer and the retailer.

Silkscreen Printing in the Packaging

An older, yet more effective method of silkscreen printing is widely used in packaging because of its stability and flexibility. This involves applying ink through a mesh stencil onto the surface of the packaging where images are raised maintaining vivid color even after designs have been subjected to wear and tear. Compared with other printing techniques, silkscreen printing can be processed in many different types of substrates like plastics, glass, metal, and textiles therefore suitable for the packaging requirements of different products.

Applying Techniques of Silkscreen Printing

This is true because silkscreen printing also possesses one of the major benefits of helping to improve brand visibility. The technique delivers high opaques and vibrant colors so that logos, texts, and graphics fully grasp the external packaging. This is especially noteworthy in the case of food retail stores where the product needs to stand out in sight of other tangible products. Through the effective use of silkscreen prints, the breaks of each product become easily recognizable, thereby making consumers recognize and stick with the brands.

The technique also enables designers to place various other extraordinary designs that other forms of printing may not offer. For instance, it can formulate slightly elevated surface patterns or shiny sheens that create elements of touch on the packaging. These haptic attributes not only add value to the product making it more attractive to the users but also give the product a more expensive and luxurious perception that can explain the higher price.

Labeling, Silkscreen Printing, and Combined Usage

Used together, labeling and silkscreen printing allow for great interaction between both forming an efficient synergy in increasing functionality and enhancing the beauty of a packaging. It is the labels that contain all the necessary data and branding images while silkscreen printing adds another layer of thickness and at the same time makes the packaging more attractive and durable. Collectively, the integration enables brands to provide a harmonized and persuasive message to consumers to encourage sales and brand association.

Conclusion

Labeling and silkscreen printing are inseparable components of successful packaging throughout the competitive consumer products market environment. Besides meeting the legal and informative functions they perform the functions of branding and consumer communication. Purchasing superior quality labeling and silkscreen printing is a way that brands can make their products more attractive in the market, leave a good impression behind, and make sure that their packages are sturdy together with being visually appealing to the eyes even after they have been used for some time.